|

Maintenance and repair welding cases

Wear-Management offers an efficient co-operation environment between your organisation and specially selected experts.

Take advantage of our experience and our data base.

Hydropower plants:

The most common steels used for hydropower components is the martensitic 13/4

CrNi steel. This steel offers good mechanical characteristics, satisfying

machinability, weldability and considerable resistance against erosion and

cavitation. Yet, combining all these different features is a compromise to a

certain extent.

Cavitation occurs to varying degrees throughout the wide spectrum of hydraulic

machine types, sizes and ages. Cavitation produces local elastic and/or plastic

deformation of the surface and provokes surface tearing or surface fatigue.

The length of the incubation period depends on both cavitation intensity and the

material's resistance / suface finish.

Heavily worn Pelton wheel

Sand erosion occurs to areas subject to turbulence or changes in direction.

In order to characterize the behaviour of each coating material against

sand erosion, tests were performed on specimens with a special device

developed at the Swiss Federal Institute of Technology of Lausanne.

After the first qualification with a speed of 65 m/s and an angle of

15 degrees for many different coating materials, the HVOF (WC/Co/Cr)

and Arc Spraying gave the best results. They were then used for further

experimentation in varying the speed and the angle.

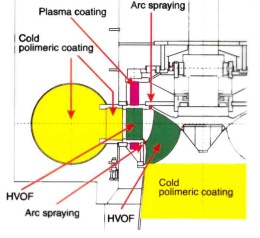

Actually, there is an increased need for tailor-made coatings to improve

wear resistance of turbine components. A broad range of coating systems

is proposed such as HVOF, Plasma, Arc spraying, Welding and Cold Polymeric

Coating Systems.

Selected coatings for Francis turbines

Increased availability and efficiency of hydropower plants and the protection

or repair of expensive components is the final objective of Wear-Management.

Surface protection technologies such as HVOF or arc spraying as well as

new materials for welding offer the possibility of optimized wear solutions.

Thermal power station

Thermal power station: Wear-Management as a key contributor to business profitability

e-service - worldwide: wear-management - free documentation

As a member of the world's premier partner in maintenance and repair welding you have access

to our world-wide e-service.

Join online: wear-management - free

documentation.

Individual Membership Annual Dues $ 140.00 or € 100.00 or CHF 140.00

No Annual Dues for Student Membership.

Guarantee yourself the peace of mind that a quality support staff is standing by to assist you when you need them.

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|