|

Maintenance and repair welding cases

Wear-Management offers an efficient co-operation environment between your organisation and specially selected experts.

Take advantage of our experience and our data base:

Exemple:

e-service

Steel works: Mail from Asia

Our approach was sent the next day.

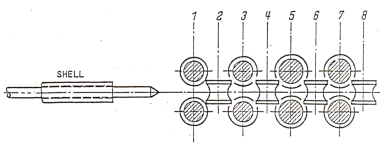

Seamless Pipe Manufacturing

How to optimise Life Cycle Costs (LCC) of tools for seamless pipe manufacturing?

Plugs for seamless tube manufacturing

Surface temperature up to 1200°C.

For seamless pipe manufacturing, four different mills are applied:

- Piercing mill

- Elongating mill

- Mandrel mill, e.g. MPM

- Plug mill

Following combinations of mills are usual:

- Piercing mill – Elongating mill – Plug mill

- Piercing mill – Mandrel mill

- Piercing mill – Plug mill

Multi Stand Pipe Mill (MPM)

Plug and mandrel handling represents about 30% of seamless pipe manufacturing costs.

e-service - worldwide: wear-management - free documentation

As a member of the world's premier partner in maintenance and repair welding you have access

to our world-wide e-service.

Join online: wear-management - free

documentation.

Individual Membership Annual Dues $ 140.00 or € 100.00 or CHF 140.00

No Annual Dues for Student Membership.

Guarantee yourself the peace of mind that a quality support staff is standing by to assist you when you need them.

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|