Welding of common steels

Unalloyed steels

Unalloyed steels are prone to cold cracking. In many cases preheating is

required to ensure good weldability.

Preheating:

| C < 0.2 %: |

|

without preheating (up to 30 mm thickness)

or 100°C against humidity |

| C: 0.2 to 0.5 %: |

|

preheating temperature 100 to 300°C |

| C > 0.5 %: |

|

preheating temperature 300 to 350°C |

Possible post-weld treatments:

- Stress relieving

- Normalising

Low alloy steels

Low alloy steels are prone to cold cracking. In many cases preheating is

required to ensure good weldability.

Preheating:

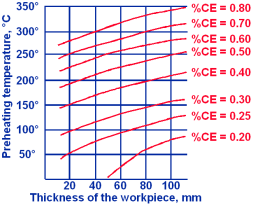

Séférian diagram

Possible post-weld treatments:

- Stress relieving

- Quenching and tempering

Fine-grained steels

Fine-grained steels are prone to cold cracking due to hydrogen absorption. They

should be preheated slightly and welded with a relatively low specific energy,

to reduce the heat-affected zone.

Preheating: in function of steel, generally 100°C (max. 200°C)

Welding: with moderate energy input per unit of length

Post-weld treatment: usually not necessary

Manganese steels

Austenitic manganese steels with a manganese content of 14% (Hadfield steels)

have a tendency to form brittle precipitates in the form of carbides.

It is essential to weld them without preheating, even with additional cooling,

and to keep the specific heat input low.

Preheating: none (cooling may be used if needed)

Possible post-weld treatments: none

Austenitic stainless steels

Austenitic stainless steels are prone to hot cracking and so should be cleaned

and welded with a low specific energy

Weldability: Watch for formation of chromium carbide at grain interface, if

carbon content is higher then 0.04%

Preheating: Usually none

Filler metal: % C = max. 0.04 %

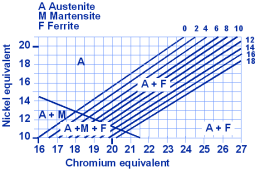

DeLong diagram

Welding: With moderated energy input per unit of length

Post-weld treatment: Solution heat treatment, where necessary

Remarks: Keep away from oil and grease, clean painstakingly after welding, use

stainless steel brushes

Martensitic chrome steels

Weldability: limited

Preheating: 250°C to 450°C (in function of composition)

Postweld treatment: Slow cooling to 120°C (martensitic transformation) and

annealing at 750°C or hardening (generally 1000°C/oil) and tempering (generally

750°C).

Watch for formation of chromium carbide between 500°C and 650°C!

Safety: Arc welding

see chapter safety

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|