Safety

... and the risks in maintenance.

To improvise is the origin of various risks.

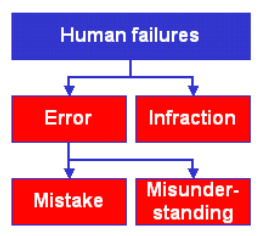

Human failures

Human failures and their roots (SwissRe)

Planning and instructions

For safe and efficient working, all procedures must be planned in detail. Special risks have to be

eliminated. Instruction about safety is necessary before every repair work.

Breaks are important for recovering and relaxing.

(SUVAPRO: Ergonomie, Erfolgsfaktor für jedes Unternehmen)

Arc welding

Personal protection

Use suitable protective clothing and approved helmet / glasses

Use a supply of fresh air to dilute ambient atmosphere

Isolate the hot workpiece to prevent inadvertent contact (warning signs)

Removal of contamination and protective coatings before welding

Use a fume extractor or suitable ventilator to remove fumes from atmosphere

Work in suitable welding position to minimise risk of inhaling fumes - working

back-to-wind when outside

Risks of electrocution

The following are examples of situations involving increased risk of

electrocution:

Workplaces where there is limited freedom of movement, requiring the welder to

kneel, squat or lie and exposing parts of the body to contact with electrically

conductive materials

Workplaces which are either wholly or in part circumscribed by materials which

are electrically conductive and with which the welder will inevitably come in

contact, perhaps accidentally

Wet, damp or hot conditions which might diminish natural body resistance and

render inoperative any insulating properties of the work materials.

Legislation differs in each country.

Noxious gases

Ozone (O3)

Intense ultraviolet radiation from the arc can transform ordinary air oxygen

into ozone which, if inhaled causes irritation of the mucous membrane and

respiratory passage.

Symptoms: eye irritation, dry throat, coughing.

Phosgene (COCl2)

Chlorinated hydrocarbon vapours (e.g. trichloroethylene) are transformed by

intense radiation into phosgene, an extremely poisonous gas. It stimulates the

sweet taste buds, being noticeable even in small concentration.

Safety precautions:

- Use of fume extractor

- Systematic ventilation of the workplace

- Avoid welding in proximity of chlorinated hydrocarbons.

Fire protection

Do not weld in areas with explosion risks

Protect joints and gaps to avoid accidental drops of molten metal

Use fire-protective screens

Remove anything inflammable, dampen any endangered materials

Cooling by water of areas adjacent to the welding zone

Collect molten drops in water or wet sand, etc.

Electrical equipment and machines can if laid on the top of the workpiece cause

short circuit in the earthing.

Gas cylinders

- Make sure the cylinders cannot fall over

- Keep the cylinders away from any source of heat

- Never use oil and grease on the valves or pressure regulators

- When the job is finished, close the valves and pressure regulators

- In the event of gas leak, or a fire, shut the cylinder valves immediately - cool any cylinders extensively with water.

Powder flame spraying, arc spraying, HVOF and plasma spraying

Workshop and work station: to consider

Supply of fresh air and local extraction of gases, vapours, fumes, overspray,

etc.

External influences / Protection of surroundings

Observe safety rules on

Gas cylinders, pressure regulators

Gas pipes / Flexible hoses

Safety devices

Spray guns (or torches)

Manipulators and mechanical positioning devices

Protection devices

Personnel protection measures against

Visible and invisible rays and the flame

Noise (up to 130 dB)

Danger of falling objects (production areas, on site, etc.)

Gases, vapours, fumes and overspray

Fire prevention includes

Authorisation to do the work

All combustible objects are removed from the place of work

Arrangement of gas cylinders, tightness of connections and hoses

Emergency exits remain always free

Having ready appropriate fire-fighting materials

Working in closed spaces - heightened danger

Contamination of the air in the space with gas, vapours, fumes or overspray which are

noxious or inflammable

Oxygen starvation of the air = danger of life !!

Artificial aeration with oxygen = danger of life !!

Heightened electrical danger

Inappropriate supervision

Difficult emergency exits

Heightened electrical danger

Workplaces where there is limited freedom of movement, requiring the welder to

kneel, squat or lie and exposing parts of the body to contact with electrically

conductive materials

Workplaces which are either wholly or in part circumscribed by materials which

are electrically conductive and with which the personnel will inevitably come

in contact, perhaps accidentally

Wet, damp or hot conditions which might diminish natural body resistance and

render inoperative any insulating properties of the work materials.

Legislation differs in each country.

Brazing

Personal protection

- Use suitable protective clothing and approved glasses/ infrared and visible

- Use a supply of fresh air to dilute ambient gases

- Use a fume extractor or suitable ventilator to remove fumes from atmosphere

- Work in suitable position to minimise risk of fume by inhalation - working

back-to-wind when outside

- Remove all contamination or protective coatings

- Isolate the hot workpiece to prevent inadvertent contact (warning signs)

If filler metals with Cadmium are overheated, cadmium fumes can be generated.

Fluxes

- Protect the eyes

- Avoid hand / skin contact

- Ensure proper ventilation

- Wash carefully after accidental skin contact

- Retain fluxes in original sealed containers after use - store in accordance with recommendations

Fire protection / Explosion protection

- Keep a safe distance, use fireproofed protective screens

- Remove anything inflammable, dampen any endangered materials

- Dont work in zones where there is any danger of an explosion

- Cooling by water of areas adjacent to the brazing zone

- Avoid unburned gases are trapped in cavities or reaching other sites

Gas cylinders

- Make sure the cylinders cannot fall over

- Keep the cylinders away from any source of heat

- Never use oil and grease on the valves or pressure regulators

- When the job is finished, close the valves and pressure regulators

- In the event of gas leak, or a fire, shut the cylinder valves immediately - cool any cylinders extensively with water.

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|