Life is competition - Ben, Olympic Museum Lausanne, Switzerland

Take advantage of our experience and our data base with more than 600 maintenance and repair cases.

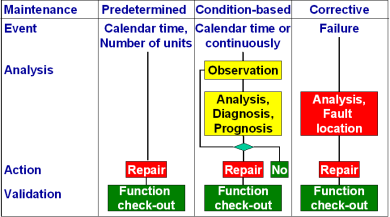

Main maintenance types and strategies:

Maintenace Welding - an efficient support

Corrective maintenance

- Corrective maintenance: Maintenance carried out after fault recognition and intendes to put an item into a state in which it can perform again (Reactive maintenance, break down mode)

- Repair: Physical action taken to restore the required function of a faulty item.

Repair welding:

Procedures and supervision are key factors for success

- Deferred maintenance: Corrective maintenance, delayed in accordance with given maintenance rules

Preventive maintenance

- Preventive maintenance: e.g. changing components at predetermined intervals

- Scheduled maintenance: Preventive maintenance carried out in accordance with an established time schedule or established number of units of use

Preventive and corrective maintenance

- Predetermined maintenance: Preventive maintenance carried out in accordance with an established time schedule or established number of units of use but without previous condition investigation

- Condition based maintenance: Preventive maintenance based on performance and/or monitoring (change

or repair just prior to failure)

- Predictive maintenance: Condition based maintenance carried out following a forecast

Predictive maintenance significantly reduces maintenance expense and increases operating performance.

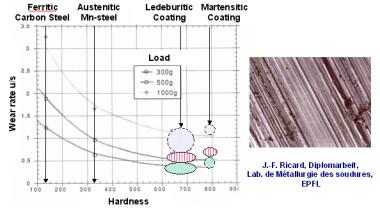

Wear rate measurements: Coating pays dividends !

Proactive maintenance

- Proactive maintenance: Predictive maintenance combined with improvements

Proactive coating improving life cycle costs

Less than 10% of manufacturing facilities practice a proactive maintenance strategy;

the vast majority is reactive or planned maintenance.

Best practice - our approach to success

Best practice can be applied through copying, re-engineering or the development of better

solutions.

Reshaping maintenance activities needs a clear understanding of modern methods and procedures.

They are documented in a systematic manner.

Wear Management: Let's be champions of change and improvement!

Availability and performance improvement as well as maintenance and spare part cost

reduction through scheduled, predictive or proactive maintenance, combined with an easy-to repair

approach are realistic results of cost-effective wear-management.

Many Original Equipment Manufacturers (OEM) still consider ferritic, martensitic or even

austenitic steels as wear resistant. For many years, scientific efforts were focussed on these

steels, their weldability and use.

Sustainable development:

Wear and tear cannot be avoided,

but they can be optimised by an efficient wear-management

Recently, the tendency changed and it was generally accepted that wear could be located in such

a way that expensive components are no longer in direct contact with heavy wear mechanisms.

Surface protection by coating is the new proactive trend increasing LifeTime, Availability and Mean Time

to Repair or Failure (MTTR or MTTF) of expensive machinery components.

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|