How to choose the Best Coating System

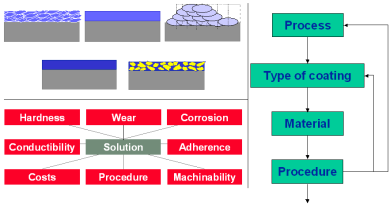

For selecting the most appropriate coating system, different criteria should be

taken into consideration, such as:

- Maintenance type and strategy (predictive or corrective)

- Wear resistance and thickness of coatings

- Mechanical properties of coatings (pressure, impact, temperature)

- Corrosion resistance of coatings

- Surface position during the coating procedure

- Amount of heat input during coating

- Necessity for preheating or postheating

- Repairability of coatings

Price/efficiency ratio, economic priorities and specific needs are other

important criteria for decision making.

Furthermore, for repair coating it is of interest to know if dismantling is

necessary or if in situ repair is possible.

Coating selection:

Procedure for coating selection

Wear mechanisms

- Friction / adhesion

- Abrasion

Abrasion

Erosion: Heavily worn Pelton wheel

Cavitation: Agitator propeller

Surface Fatigue: Tread of wheel (railway)

Combined wear: Hot working die

Systematic wear analysis

- Design properties

- Base body (initial stage)

- Opposing body / Intermediate body

- History

- Base body (final stage)

- Special parameter / properties

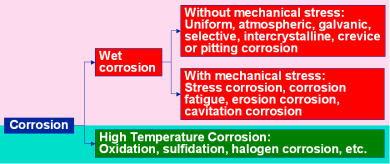

Corrosion mechanisms

Different types of corrosion

- Wet corrosion - without mechanical stress

Uniform corrosion

Crevice corrosion

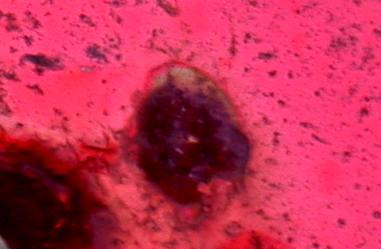

Pitting corrosion

- Wet corrosion - with mechanical stress

Stress corrosion,

Microsection

High temperature corrosion

combined with erosion,

Stainless steel,

Drying plant - Cement work

Hardness test

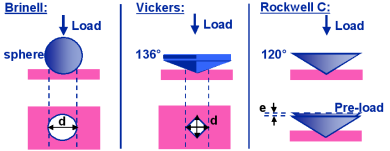

The hardness tester forces a small sphere (Brinell, HB), a diamond pyramid (Vickers, HV)

or a cone (Rockwell C, HRC) into the surface of a metallic material.

Hardness tests

Tensile strength

N/mm2 |

|

Vickers

HV |

|

Brinell

HB |

|

Rockwell C

HRC |

| 720 |

|

225 |

|

214 |

|

--- |

| 800 |

|

250 |

|

238 |

|

22.2 |

| 880 |

|

275 |

|

261 |

|

26.5 |

| 985 |

|

300 |

|

285 |

|

29.8 |

| 1125 |

|

350 |

|

333 |

|

35.5 |

| 1290 |

|

400 |

|

380 |

|

40.8 |

| 1485 |

|

460 |

|

437 |

|

46.1 |

| 1665 |

|

510 |

|

---- |

|

49.8 |

| 1845 |

|

560 |

|

---- |

|

53.0 |

| 2039 |

|

610 |

|

---- |

|

55.2 |

| 2180 |

|

650 |

|

---- |

|

57.8 |

| ------ |

|

700 |

|

---- |

|

60.1 |

| ------ |

|

800 |

|

---- |

|

64.0 |

| ------ |

|

900 |

|

---- |

|

67.0 |

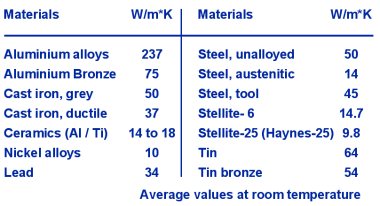

Thermal conductivity

Thermal conductivity

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|