|

We promote savings-through-dependability improvements of your equipment and components.

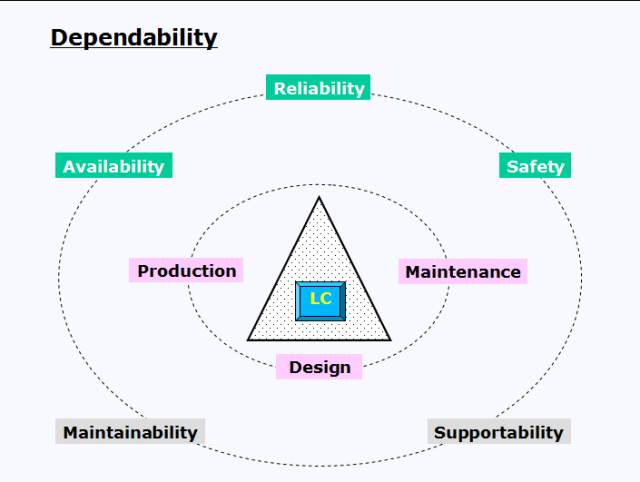

The word dependability means ability of a system (asset) to perform a required function under given conditions for a given time interval (including failures and maintenance).

Dependability includes three major aspects:

- Reliability performance: ability of a system (asset) to perform a required

function under given conditions for a given time interval (including failures but

not maintenance, e.g. time between failures)

- Maintainability performance: ability to maintain or restore functions, e.g. duration

of the maintenance actions

- Supportability performance: ability of a support organisation of having the

right support (personnel and competency, tools, spare parts, etc.) at the necessary

place to perform the required maintenance activity at a given instant of time or

during a given time interval

Positioning of dependability

Sources:

IEC 56/60300-3-14.Ed. 1

EN 13306: 2001

Dependability analysis

Failure rate prediction

Failure rate prediction of components.

The estimation may be based on:

- tests

- comparison to similar components

- experience from the field

At the end it should be possible to calculate the failure rate

of the complete system (asset).

System dependability analysis

For a system (asset) the dependability and the reliability can be

calculated or analysed from the failure rate of each component.

The structure of the system is described in a block diagram which

shows the system (asset) from the perspective of dependability or

reliability.

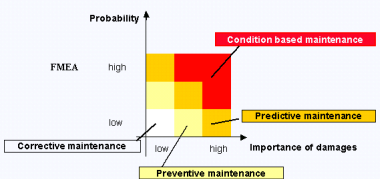

Failure Mode and Effect Analysis (FMEA)

FMEA is another approach to determine the impact of component failures.

The consequences on the component and the entire system are described.

The analyse can be qualitative or even quantitative depending on the

purpose of the analyse.

If system failure can occur as a result of a combination of several

failures, other methods must be considered.

Failure Mode and Effect Analysis (FMEA)

Fault tree analysis (FTA)

FTA is a method for analysing complex failure situations. It gives good

understanding of dependencies and how failures occurs.

FTA is used in Probabilistic Safety Analysis (PSA).

Maintenance Need Analysis (MNA)

For all failing systems or components, maintenance is a key factor.

Regardless of how maintenance is performed questions like which tools

and test equipment, which training and support are needed will rise up.

Repair-discard analysis

Systems (assets), subsystems or components which fail can either be

repaired or discarded. In the repair-discard analyse are considered

both technical and economic aspects. This analyse must kept up to date

during the entire life-time.

Technical aspects consider the possibility to repair.

The economical aspects covers e.g. man-hours, equipment, spare parts,

storage, transportation, outsourcing and administrative costs.

The analyse shows which alternative would be the best solution.

Level of Repair Analysis (LORA)

LORA is designed for systems, subsystems or components needing maintenance.

It covers preventive and corrective maintenance. The word "level" indicates

on which level maintenance and repair should be performed: e.g. by the operators,

dedicated maintenance personnel, specialised maintenance workshops or by

suppliers.

The objective is to describe different alternatives and their costs

(e.g. for training, acquiring of maintenance resources, supervision, spare parts, tools, test equipment, etc.)

LORA is useful in larger organisations (airlines, transport companies,

cement or mining industry and car industry).

In the field of heavy maintenance and repair LORA is a very helpful tool for optimising spare part costs in function of operational consequences.

Spares optimisation

Often, spares are the largest part of maintenance costs. The aim should be

to find a cost-effective assortment of repairable spares to fulfil

dependability requirements such as operational availability.

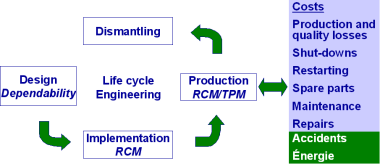

Life Cycle Profit / Life Cycle Cost analyse (LCP / LCC)

The aim of this approach is to achieve a more cost-effective system (asset).

Life Cycle Profit / Life Cycle Cost analysis are very important as they gathers

information from other analyses and focus on economical aspects. Inventory costs

are includes in the Life Cycle Costs.

Life Cycle Management

Life Cycle Profit / Life Cycle Cost analysis consider the system (asset) and

the necessary support. Often it becomes evident that few of the cost elements

represent the major part of the actual costs. This gives a hint on where to

focus in order to achieve highest cost-effectiveness and sustainability

with design or dependability improvements.

For further information, on-site training, technical advise or project management, please do not hesitate to

contact us.

|